When considering the finish and appearance of molded products, several factors are important to take into account.

Machined Finish of Mold

The machined finish of the mold has considerable effect on the surface finish or appearance of a rubber product.

The best finish can be obtained from a highly polished steel mold, free from all tool marks or other imperfections. However, this type of mold is quite expensive to construct and maintain. Thus, it is not generally required unless surface finish is of paramount importance from either an aesthetic or functional standpoint.

Standard “commercial finish” is a machined steel mold made to conform to good machine shop practice. Machine tool marks will not ordinarily be polished out of this type of mold.

It should be noted that regardless of how highly the mold itself is polished, the appearance of the rubber surface will also largely depend upon the following factors.

Type of Rubber Material

The type of rubber material used can greatly affect the appearance of the rubber product. Some compounds lend themselves to a bright, glossy surface, while others may be dull when molded, or become dulled very easily during handling or storage.

Additionally, there are some rubber compounds to which antiozonants are added in an effort to impede attack from ozone. As these compounds age, the antiozonants “bleed out,” giving the product a colored or waxy surface. This is a common occurrence, and the product should not be considered imperfect or defective in any way. The usage of antiozonants, or other specification requirements, may make it impossible to produce parts with uniform surface finish.

Mold Release

Rubber compounds generally require the use of lubricant for proper release of parts from the mold. This lubricant may have the appearance of being oily.

If the surface of the rubber product is to be bonded to other materials in its application, or is to be painted, the designer should designate this on the drawing so that the manufacturer uses a mold release lubricant that will not impair adhesion quality.

Flash Removal Method

Some of the methods used to remove flash from rubber parts may affect the appearance of the finished product. As an example, mechanical abrasion may result in a dull surface.

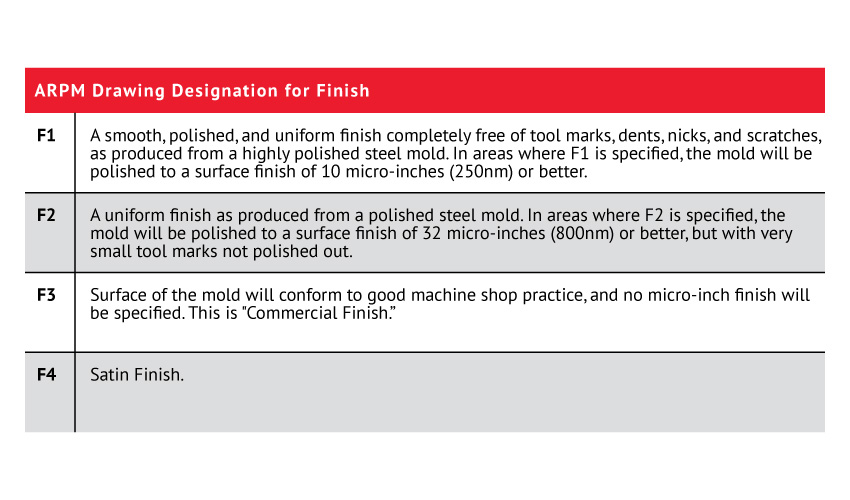

Drawing Designation of Finish

“Commercial Finish” (F3) is assumed for all part surfaces if no other drawing designation is made.

Note that these designations apply to mold surfaces. Surface roughness of the mold can be measured with a profilometer, while rubber parts themselves cannot be measured due to “grabbing” of the measuring stylus by such soft material.

Note that these designations apply to mold surfaces. Surface roughness of the mold can be measured with a profilometer, while rubber parts themselves cannot be measured due to “grabbing” of the measuring stylus by such soft material.

Special Considerations for Appearance of Urethane Parts

All the aforementioned considerations are applicable to urethane parts, with surface finish of the mold being the most relevant factor, followed by the presence of mold release.

Access more articles in our Rubber Knowledge Center and our Urethane Knowledge Center.