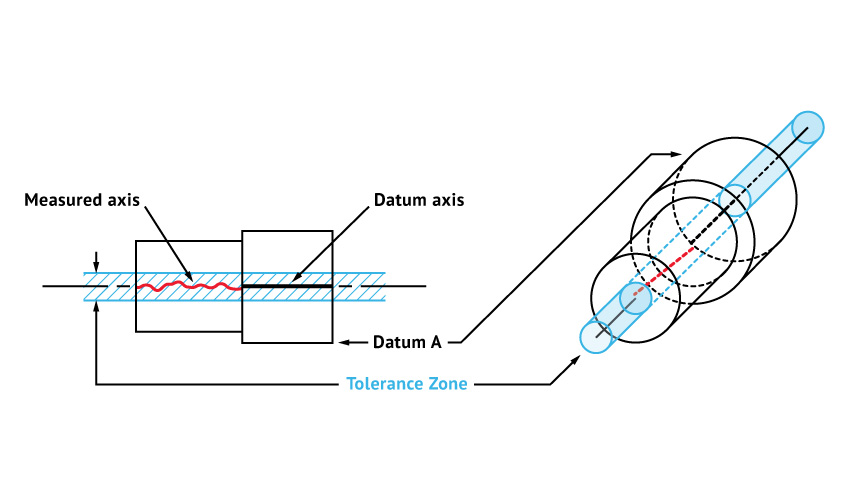

Concentricity is the relationship of two or more cylindrical features that have a common center. The center of one feature is selected as the ideal, or datum axis. Concentricity is then employed in order to establish a tolerance zone for the median points of coaxial cylindrical features. To illustrate median points, imagine a circle with two opposing points on it. The midpoint of a line drawn between those points is a median point.

Concentricity considers how a cylindrical shape is positioned on a theoretical axis. The concept is complex, in part because it relies on measurements from derived median points, as opposed to from a surface or from a feature’s axis. In fact, concentricity is considered to be one of the most difficult Geometric Dimensioning & Tolerance (GD&T) symbols to measure.

Concentricity considers how a cylindrical shape is positioned on a theoretical axis. The concept is complex, in part because it relies on measurements from derived median points, as opposed to from a surface or from a feature’s axis. In fact, concentricity is considered to be one of the most difficult Geometric Dimensioning & Tolerance (GD&T) symbols to measure.

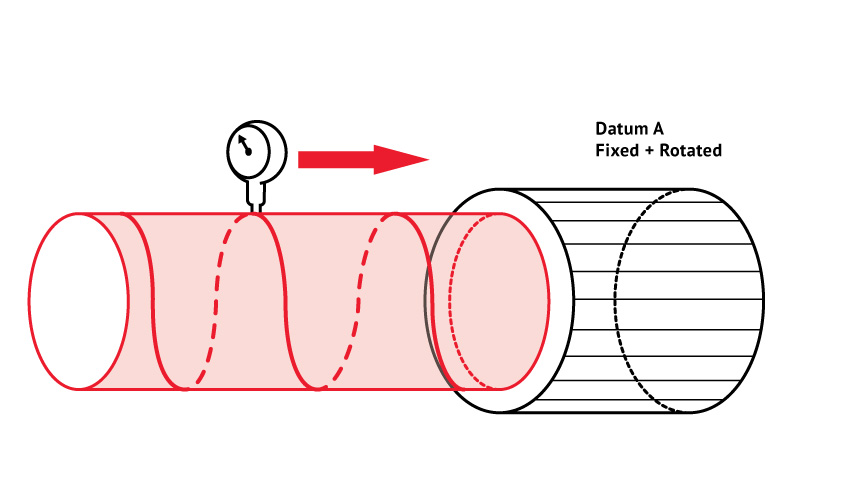

In contrast, total runout is how much an entire feature, or surface, varies with respect to a datum, when the part is rotated 360° around the datum’s axis. Total runout controls the amount of variation in the surface as the part is rotated, as well as the amount of variation in the axial dimension. Both of these variations—radial and axial—are measured and held within the determined tolerances.

Total runout is usually called for on parts that are rotated about an axis where the entire surface is critical to be in tolerance. For instance, a shaft that is rotated at high speeds is prone to oscillation. To control how much wobble this part will have, total runout is used to ensure that the smaller diameter surface is relatively controlled to Datum A in the figure below.

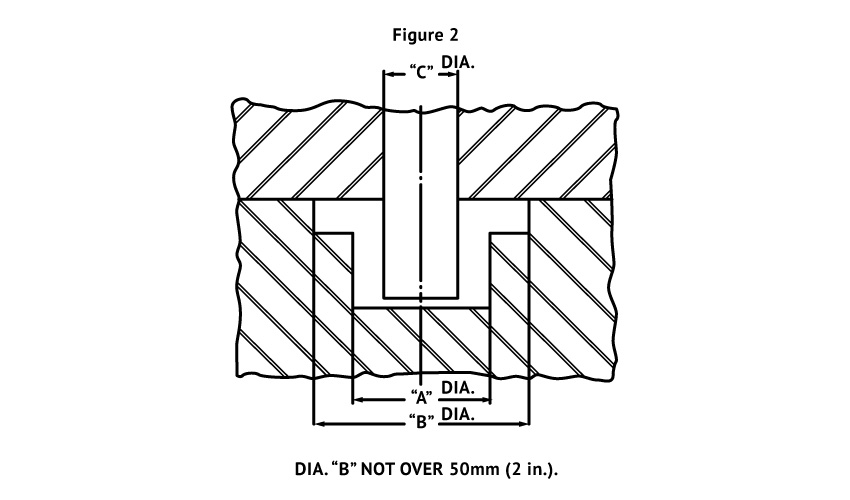

Cylindrical surfaces formed in the same mold plate (fixed dimensions) can be held to tighter Total Indicator Readings (TIR) than cylindrical surfaces that cross the parting line (closure dimensions). As a case in point, in Figure 2, diameter “B” will be within .010” TIR (0.25mm) to diameter “A,” and diameter “C” will be within .030” TIR (0.75mm) to diameters “A” or “B.”

Cylindrical surfaces formed in the same mold plate (fixed dimensions) can be held to tighter Total Indicator Readings (TIR) than cylindrical surfaces that cross the parting line (closure dimensions). As a case in point, in Figure 2, diameter “B” will be within .010” TIR (0.25mm) to diameter “A,” and diameter “C” will be within .030” TIR (0.75mm) to diameters “A” or “B.”

Access more articles in our Rubber Knowledge Center and our Urethane Knowledge Center.